Stainless Steel Materials

Universal Trade Center: Your Premier Source for Industrial Stainless Steel Materials

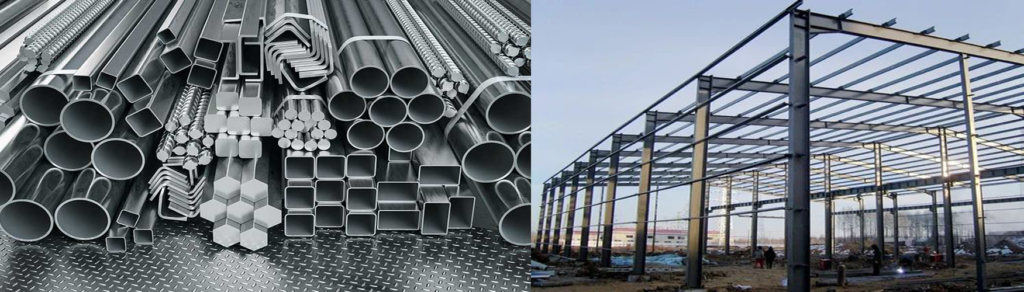

In the demanding world of industrial applications, stainless steel stands as a cornerstone material, prized for its durability, corrosion resistance, and versatility. Universal Trade Center has established itself as a leading importer, manufacturer, and supplier of all industrial stainless steel (SS) materials, serving diverse industries with a comprehensive range of products and services.

Stainless Steel Products:

Universal Trade Center offers an extensive inventory of stainless steel products to meet the diverse needs of its clientele. Their offerings include:

- Stainless Steel Sheets and Plates: Providing various grades, finishes, and thicknesses to suit a wide range of applications, from structural components to decorative elements.

- Stainless Steel Pipes and Tubes: Offering seamless and welded pipes and tubes in various sizes and schedules, suitable for fluid transport, structural support, and other industrial uses.

- Stainless Steel Bars and Rods: Supplying round, square, flat, and hexagonal bars and rods in different grades and sizes for machining, fabrication, and structural applications.

- Stainless Steel Fittings and Flanges: Providing a comprehensive selection of fittings and flanges to connect pipes and tubes, ensuring leak-free and reliable fluid transfer systems.

- Stainless Steel Valves: Offering various types of valves, including ball valves, gate valves, globe valves, and check valves, to control the flow of fluids in industrial processes.

- Custom Stainless Steel Fabrication: Leveraging their manufacturing capabilities, Universal Trade Center offers custom fabrication services, producing bespoke stainless steel components to meet specific client requirements.

Importer, Manufacturer, and Supplier: A Unique Advantage:

Universal Trade Center’s position as an importer, manufacturer, and supplier provides several key advantages:

- Wide Product Selection: Access to a broad range of stainless steel products from various sources, ensuring clients can find the right materials for their needs.

- Competitive Pricing: Direct sourcing and manufacturing capabilities enable competitive pricing without compromising quality.

- Quality Control: Stringent quality control measures are implemented throughout the supply chain, from sourcing raw materials to manufacturing finished products.

- Customization Options: In-house manufacturing allows for customization of stainless steel components to meet specific client specifications.

- Timely Delivery: Efficient logistics and inventory management ensure timely delivery of products to clients.

Core Industries:

- Food Processing: (As mentioned before) Hygienic environments, resistance to cleaning chemicals, and no flavor transfer make it essential for everything from processing equipment to storage tanks.

- Pharmaceuticals: (As mentioned before) Similar to food processing, sterility and corrosion resistance are key for manufacturing and storage.

- Chemical Processing: (As mentioned before) Resistance to harsh chemicals and extreme temperatures is vital for safe and efficient operations.

- Construction: (As mentioned before) Structural integrity, aesthetic appeal, and resistance to weathering make it ideal for building facades, roofing, and structural supports.

- Oil and Gas: (As mentioned before) Withstanding harsh marine environments and high pressures is crucial for offshore platforms, pipelines, and refining equipment.

Expanding the Scope:

- Automotive: Exhaust systems, trim, and structural components benefit from stainless steel’s durability and corrosion resistance.

- Aerospace: High strength-to-weight ratio and resistance to extreme temperatures make it crucial for aircraft components.

- Medical: Surgical instruments, implants, and hospital equipment require sterility and corrosion resistance.

- Water Treatment: Resistance to corrosion from water and chemicals is essential for pipes, tanks, and treatment equipment.

- Marine: Shipbuilding, offshore platforms, and coastal structures rely on stainless steel’s resistance to saltwater corrosion.

- Energy: Nuclear power, renewable energy (solar, wind), and traditional power plants use stainless steel for its strength, heat resistance, and corrosion resistance.

- Manufacturing (General): Machinery, tools, and equipment across various manufacturing sectors benefit from stainless steel’s durability and resistance to wear and tear.

- Consumer Goods: Appliances, cookware, cutlery, and even jewelry utilize stainless steel for its aesthetic appeal, durability, and ease of cleaning.